There

are several CAN physical layer and other standards:

•ISO 11898-1: CAN Data Link Layer and Physical Signaling

•ISO 11898-2: CAN High-Speed Medium Access Unit

ISO

11898-2 uses a two-wire balanced signaling scheme. It is the most used physical

layer in car

Powertrain

applications and industrial control networks.

•ISO 11898-3: CAN Low-Speed, Fault-Tolerant, Medium-Dependent Interface

•ISO 11898-4: CAN Time-Triggered Communication

ISO

11898-4 standard defines the time-triggered communication on CAN (TTCAN). It is

based on the

CAN

data link layer protocol providing a system clock for the scheduling of

messages.

•ISO 11898-5: CAN High-Speed Medium Access Unit with Low-Power Mode

•ISO 11898-6: CAN High-speed medium access unit with selective wake-up

functionality

•ISO 11992-1: CAN fault-tolerant for truck/trailer communication

•ISO 11783-2: 250 kbit/s, Agricultural Standard

ISO

11783-2 uses four unshielded twisted wires; two for CAN and two for terminating

bias circuit

(TBC)

power and ground. This bus is used on agricultural tractors. This bus is

intended to provide

interconnectivity

with any implementation adhering to the standard.

•ISO 15765-2 also called ISO-TP, is a standard for flow control and handling of

messages larger than eight bytes.

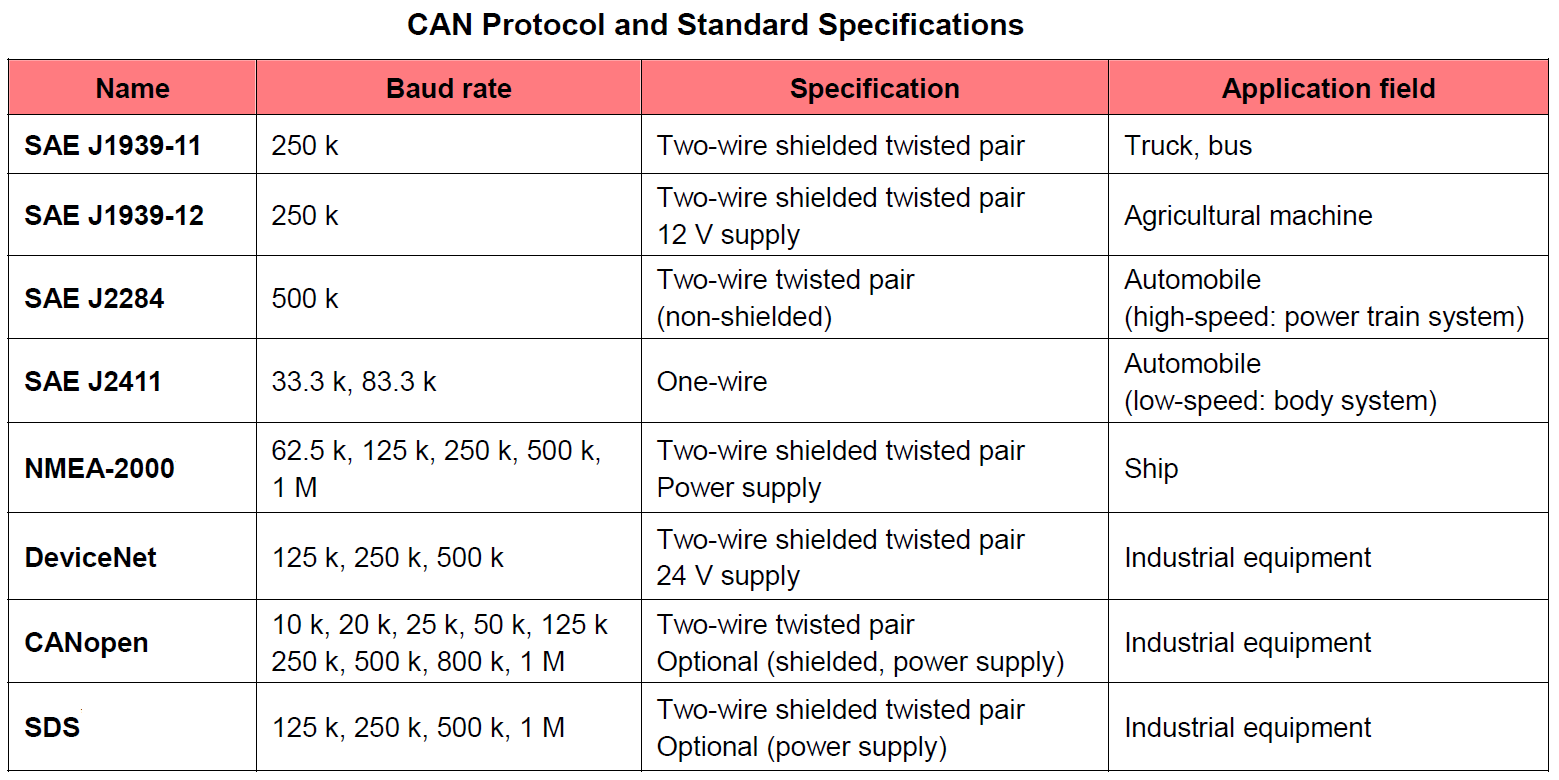

•SAE J1939-11: 250 Kbit/s, Shielded Twisted Pair (STP)

•SAE J1939-15: 250 Kbit/s, Unshielded Twisted Pair (UTP) (reduced layer)

The

SAE J1939 standard uses a two-wire twisted pair, −11 has a shield around the

pair while −15 does not. SAE 1939 defines also application data and is widely

used in heavy-duty (truck) and autobus industry as well as in agricultural

& construction equipment.

SAE = Society of Automotive Engineers; NMEA = National Marine Educators Association; SDS = Smart Distributed System