11. September 2015 09:08 by streng in

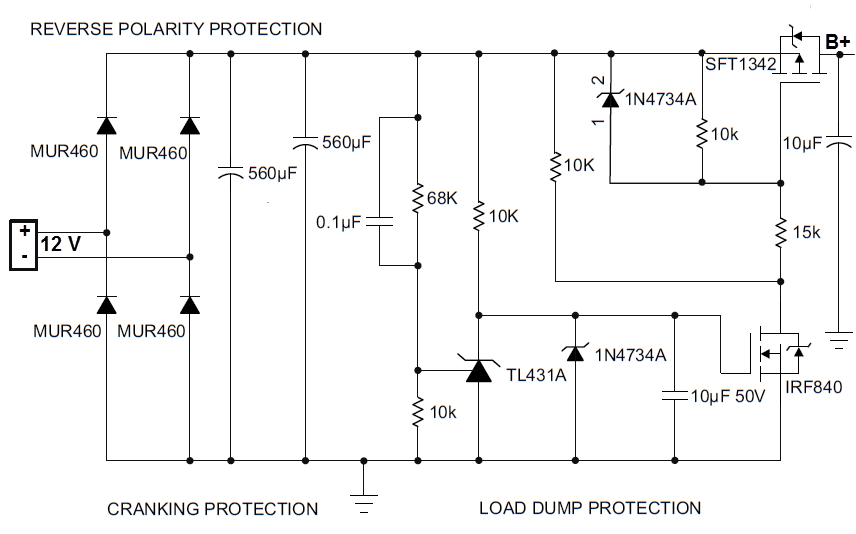

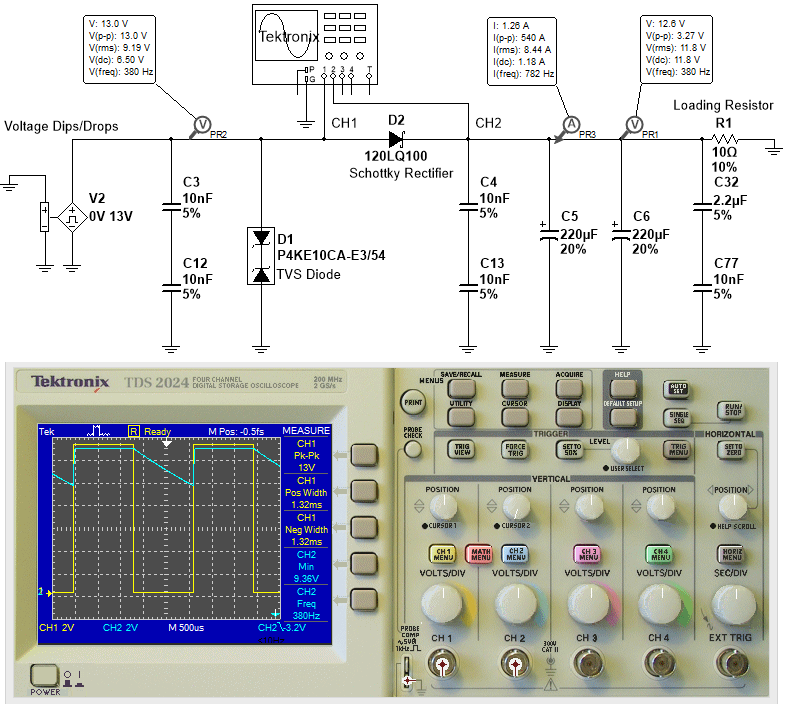

The suppliers of automotive electronic devices are competing these days to lower the cost of theirs designs. This is a sample of rather expensive solution to ensure proper function of an automotive electronic device during transients on supply lines (12V Battery).

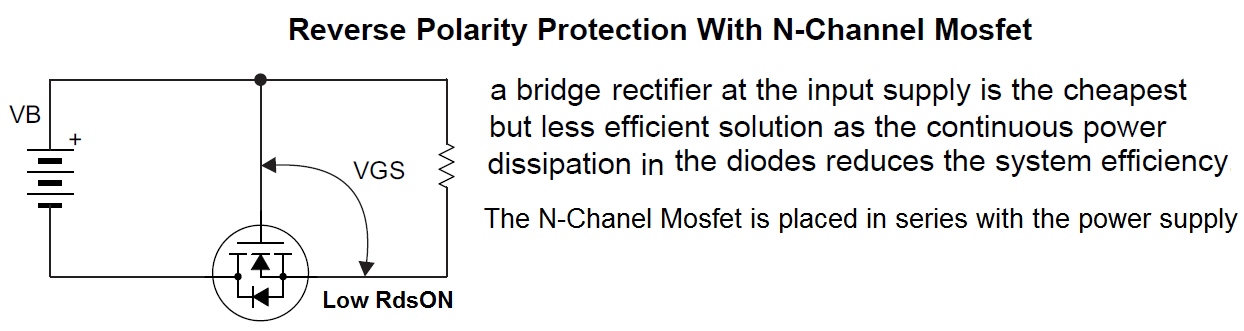

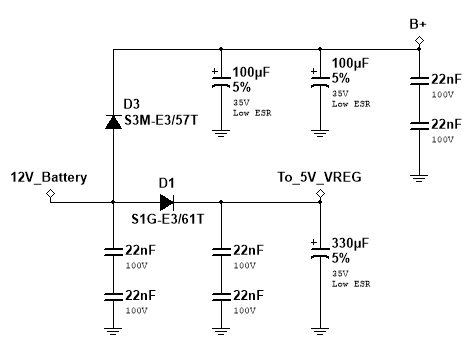

Sample of less expensive solution to prevent reverse polarity, load dump, and cranking pulse from disturbing circuits sourced from a 5V voltage regulator or directly from the 12V B+ line.

10. September 2015 20:08 by streng in

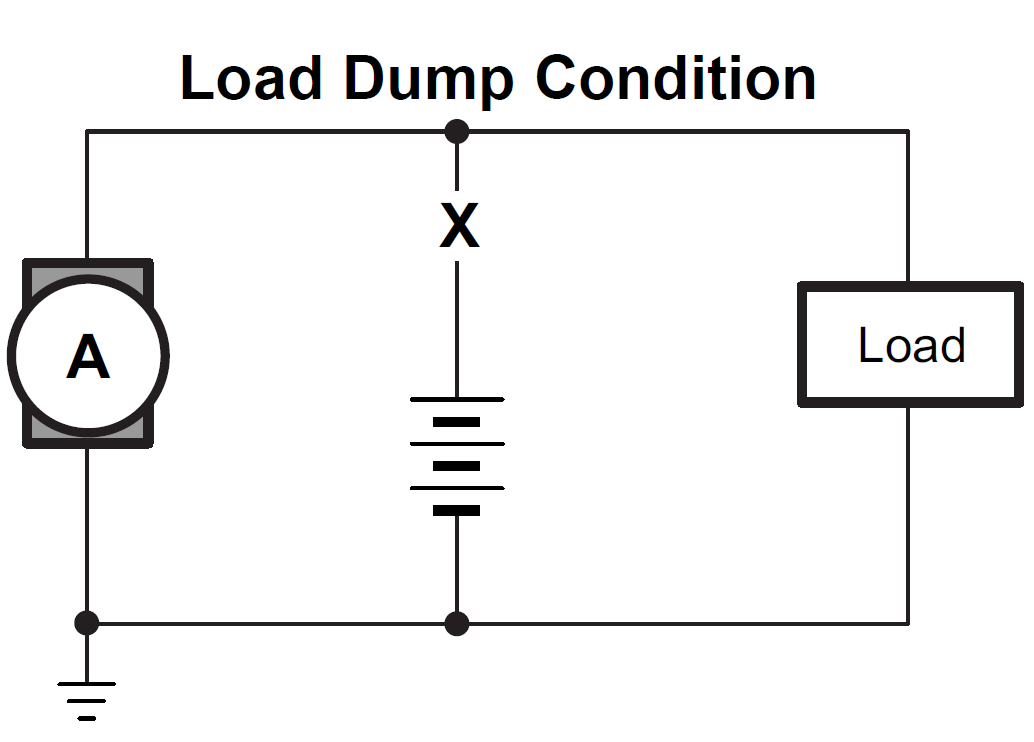

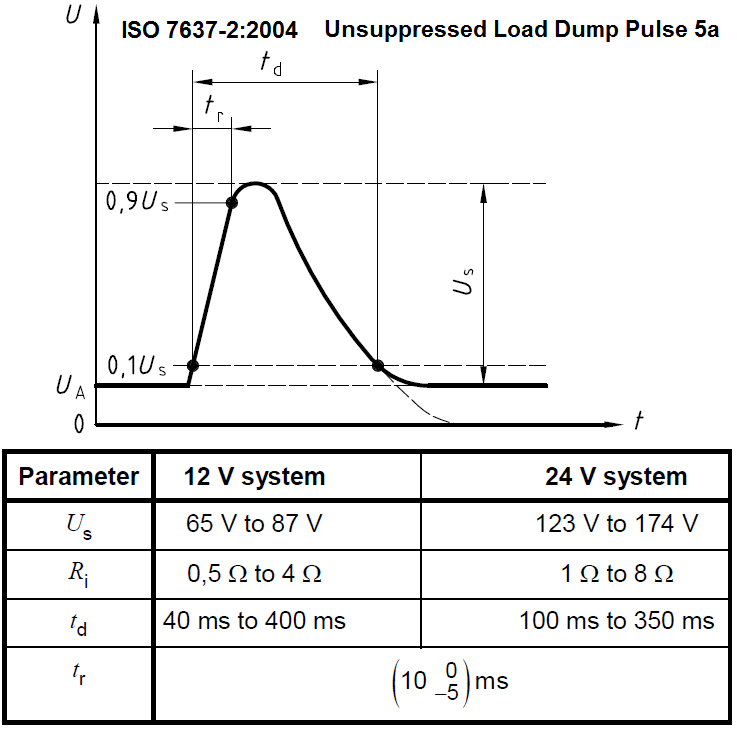

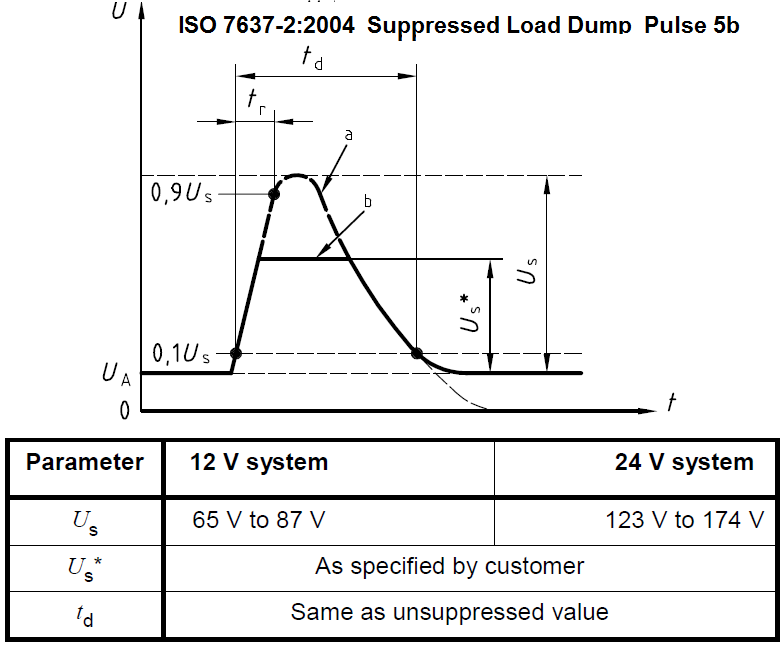

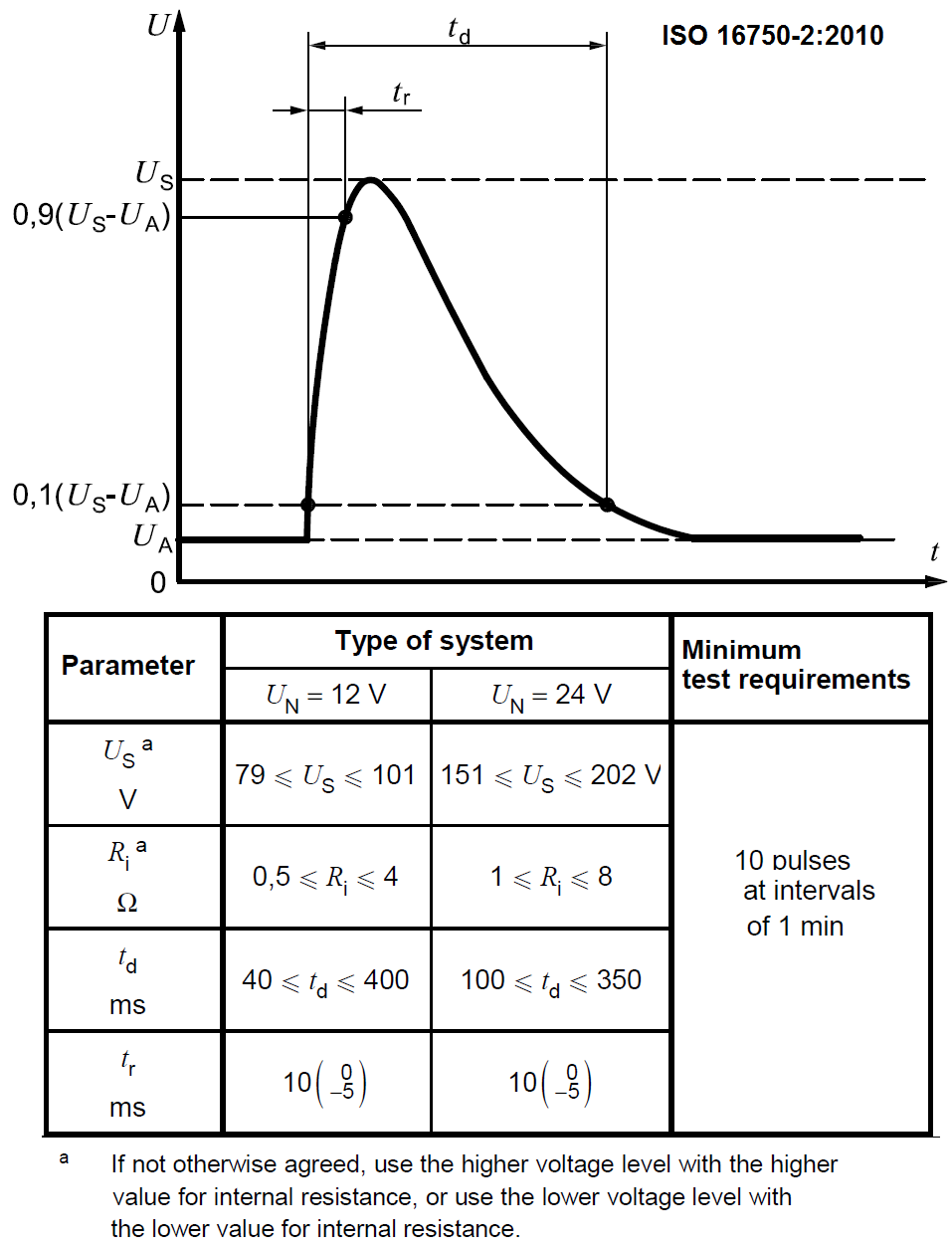

The Load Dump condition occurs when the positive terminal

from a discharged 12/24 V battery is being disconnected while the alternator is

charging. The electrical loads connected directly to the alternator are subject

to a surge of up to 120 V for 400 ms.

Load Dump as defined by ISO 7634-2:2004 and ISO 16750-2:2010.

10. September 2015 19:47 by streng in

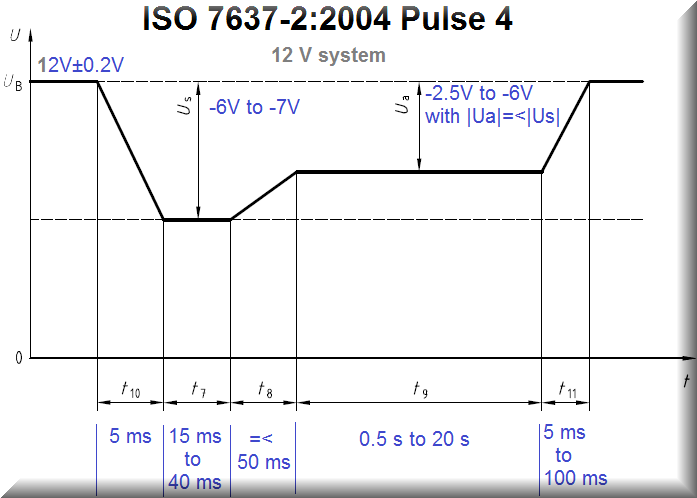

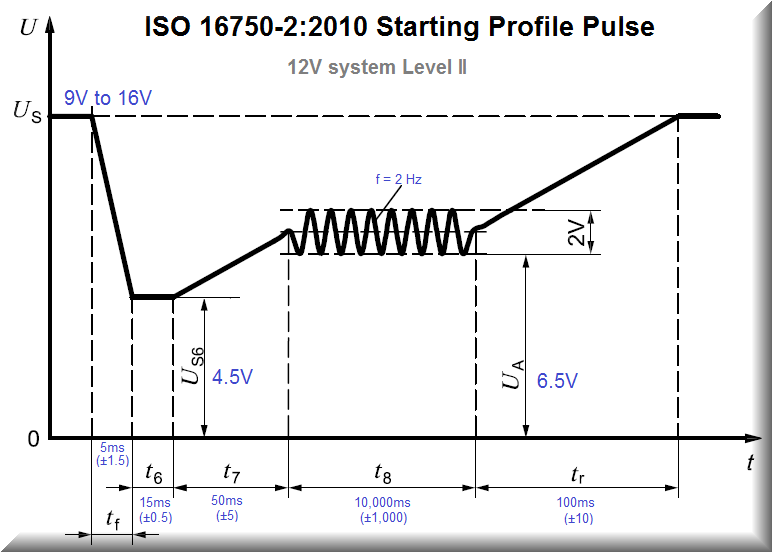

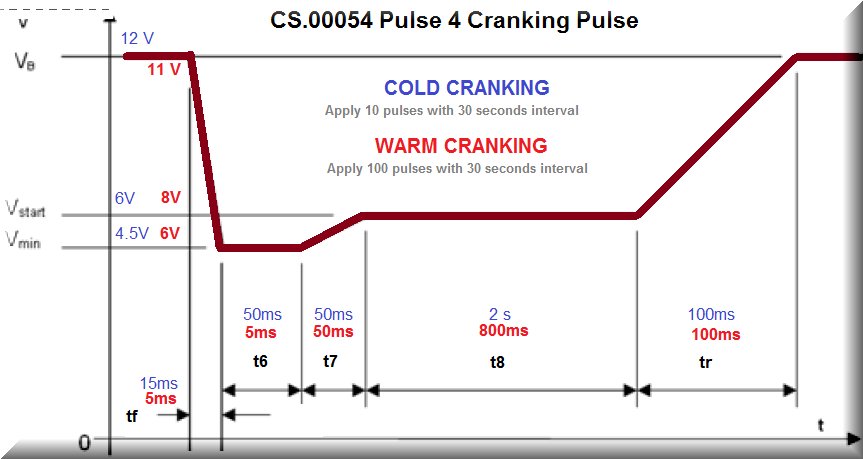

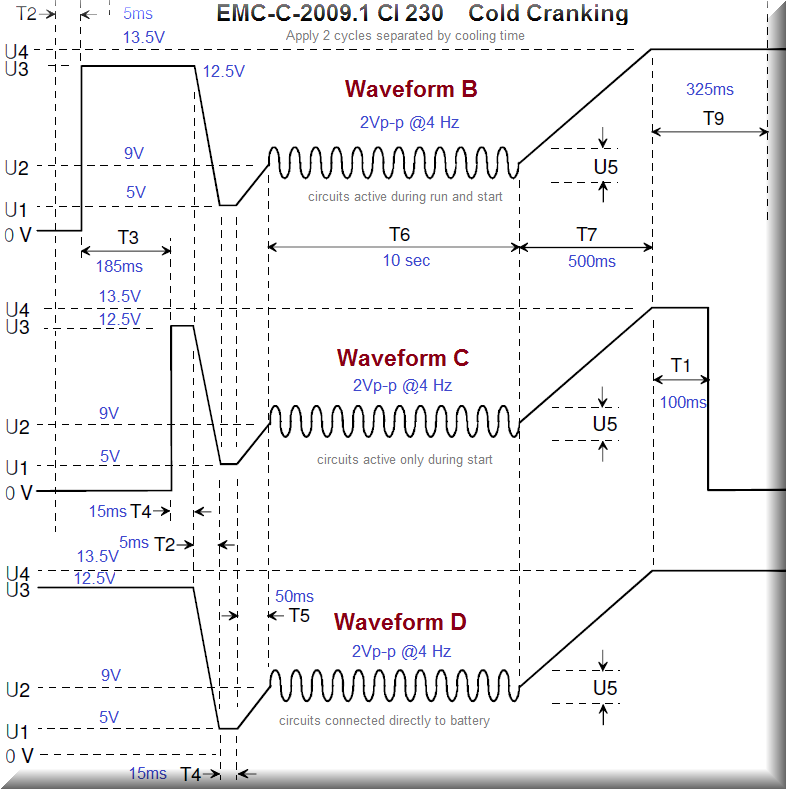

The Cold Cranking Pulse occurs when starting the engine in the morning and even worse in cold weather. Controllers supporting CAN bus will be notified that a temporary low battery voltage condition will occur. Motion controllers modules (e.g. power lift gate) driving in that moment electrical motors will have to stop the ongoing operation and store their current status (e.g. lift gate position and direction) just before the Cold Cranking Pulse occurs. Once the Battery voltage returns to nominal (e.g. 12.8 V) the motion controller should safely resume its operation.

10. September 2015 12:18 by streng in

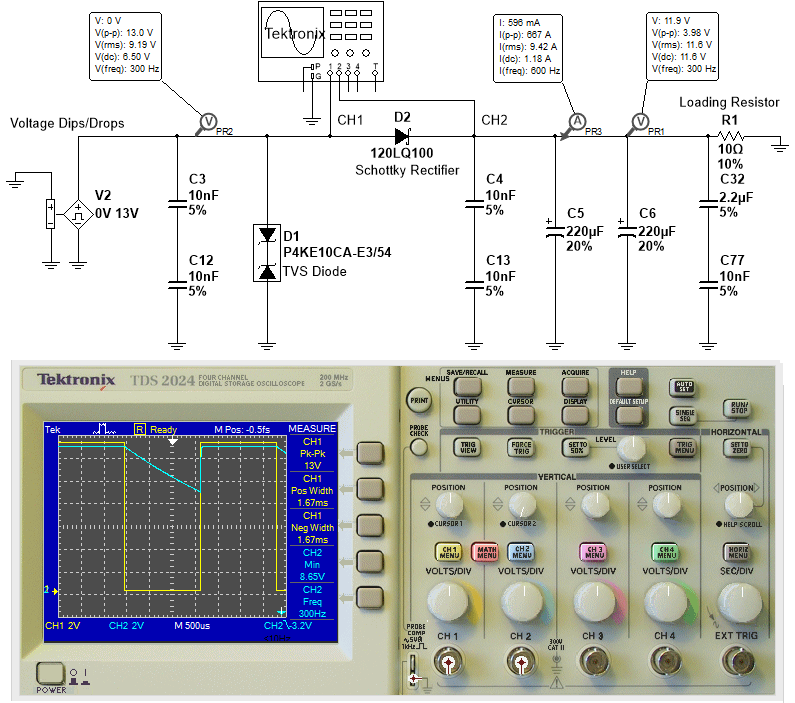

Simple simulation to prevent voltage drop issues for 9V to 16V operating voltage range devices.

All DUT's functions are required to perform as designed during battery voltage drops of up to 1 ms. For drops above 1 ms the functions are allowed to be temporarily disrupted or fail in a safe mode. Upon return to the operating voltage range the DUT is supposed to auto-recover and resume its operation. In the above example the DUT's functions should not be disrupted (dropout = 1.3 ms, B+ = 9.36 V).

In the above example (dropout = 1.67 ms, B+ = 8.65 V) a fail safe behavior is acceptable. The software will prevent the DUT from resuming its operation as long as B+ is detected below the voltage range. Once B+ line is above 9V the auto recover process should be initiated.