The accuracy of RF Field Level during ALSE RF Immunity per ISO 11452-2:2019 Substitution Method relies on the Field Probe calibration factors. An incorrect Field Probe Calibration may result in significant deviations from the field levels called by automotive OEM specs. The Field Probe Calibration Report provides correction factors that are introduced into RF Immunity Test Software (e.g. TILE, NEXIO). Using calibration factors acquired at 15 V/m instead of 300 V/m can force the RF Amplifier output to maximum w/o the Field Probe to report expected Field Level. Moving transmitting antenna 10 inches closer to the Field Probe would allow the probe to report the expected field level, however this level is in fact higher as consequence of using bad correction factors.

RF Field Probe Selection for EMC Testing

Calibration Factors: corrections are provided as dB adjustments & multiplication factors. Maximum field measurement accuracy is achieved when the detailed 3-axis calibration is applied.

Probe Calibration Certificate

A) filed level applied via calibration antenna (V/m)

B) filed level reported by probe (V/m)

C) calculated multiplier factor

A = B * C (e.g. 100 V/m = 120 V/m x 0.8333 where 0.8333 is the correction factor)

Sensitivity/Dynamic Range: e.g. (0.5 – 800V/m for 0.5 MHz – 6 GHz)

Linearity: the measure of deviation from an ideal response over the dynamic range of the probe that may vary as a function of the applied field level. (e.g. ±0.5dB 0.5 – 800 V/m).

Overload: the field level where damage can occur to the probe (e.g. 1000 V/m CW).

Isotropic Deviation: the variation of the probe’s response from ideal as it is rotated in the field. The minimal isotropic deviation of spherical probes (±0.5dB 0.5 MHz – 2 GHz).

Response time: the time a probe takes to respond to an applied RF field (e.g. 20 ms).

Sample rate: the rate at which information can be retrieved from the probe (e.g. 50 samples/second).

Probe Type: refers to the configuration of the probe sensors.

- An isotropic RF filed measures the total value of the field level and is unaffected by field polarity. This is accomplished by summing measurements from three different sensors placed orthogonal to each other.

- Non-isotropic probes measure fields in one polarity at a time for electric field or magnetic field.

IEEE 1309:2013 is the Standard for Calibration of Electromagnetic Field Sensors and Probes (Excluding Antennas) from 9 kHz to 40 GHz.

The EMC lab must inform the calibrator about critical requirements imposed by automotive specs/standards for proper field calibration factors:

- The frequency range or center frequencies as delineated by automotive OEM EMC specs (e.g CS.00054, GMW3097, FMC1278).

- The filed level for each frequency band (e.g. 80V/m, 100V/m, 200V/m, 300V/m)

- Field Probe orientation (all three axes X, Y, Z facing antenna).

- Use 1 meter antenna distance to Field Probe. This is not always possible, therefore using a lower distance in far field (e.g. 30 cm) should be acceptable.

- Calibrate the probe using CW with transmitting antenna in both horizontal/vertical polarization.

IEEE 1309:2013 A.2.4.3 Field strength: if the probe or sensor linearity is better than ± 0.5 dB, the frequency response calibration of the probe can be performed at any field strength level, but preferably close to the field levels used in the EUT tests. It is also required that the same probe range and/or gain settings as used in the EUT tests are used in the probe calibrations.

IEEE 1309:2013 A.2.4.4 Linearity check for probe or sensor:

For applications needing multiple field strength calibrations, e.g., 3 V/m, 10 V/m, and 18 V/m, the linearity tests shall be performed for each level. Note that for automotive EMC testing the above e.g. translates to levels like 100V/m, 200V/m, 300V/m.

IEEE 1309:2013 A.2.4.5 Probe isotropic response

For isotropic probes using three orthogonal elements, it is recommended that the frequency response and linearity response measurements be performed for each axis individually. Each axis should be aligned with the incident field successively to provide a maximum response. Probe calibration in a single orientation, such as only the orientation used in a UFA calibration, is not recommended, because the transmitting antennas, separation distances, and the end-use environment are typically not the same between the two setups.

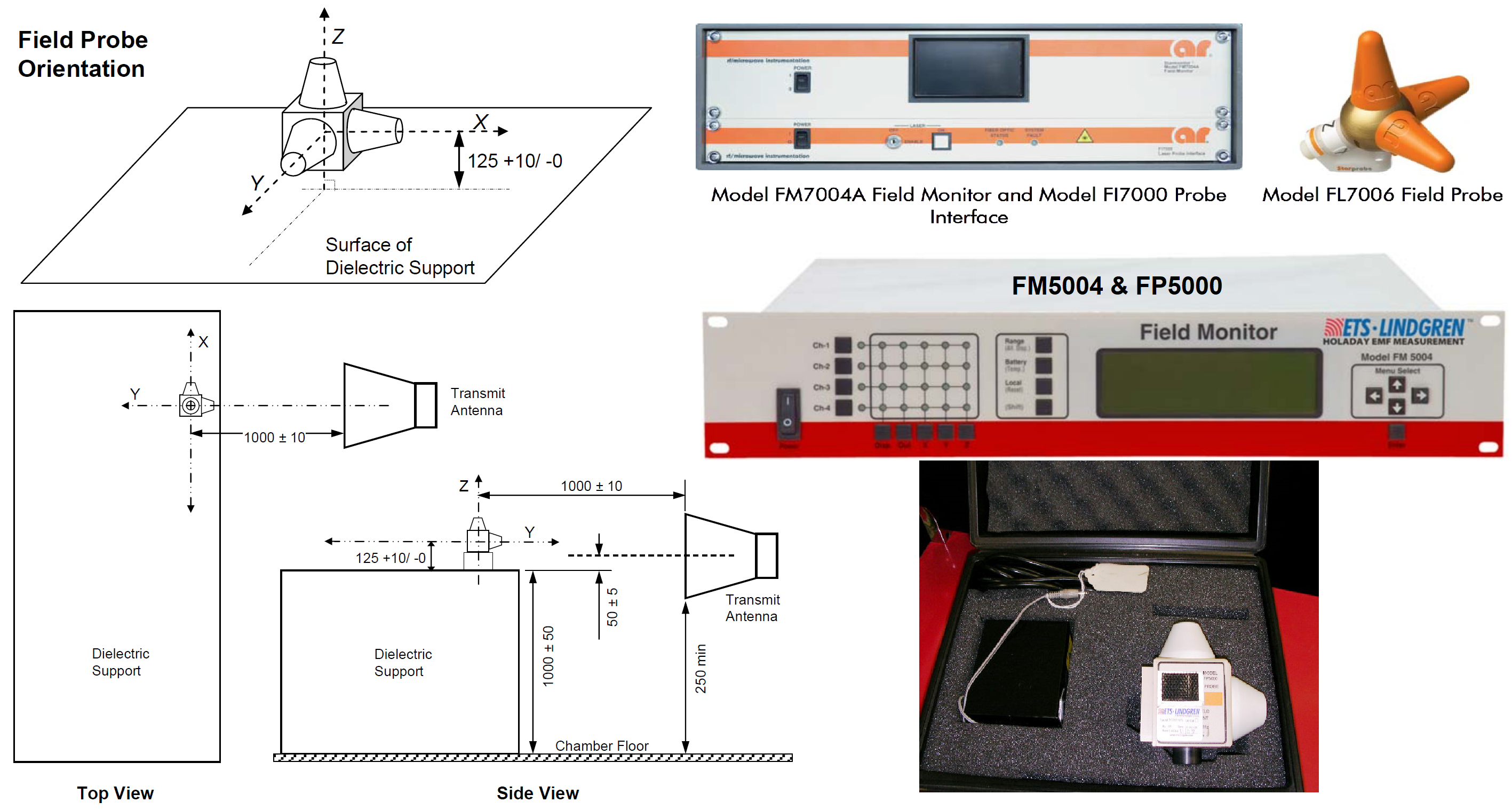

Example of RI ALSE Test Configuration

Example of Field Calibration using Field Probe Type A per FMC1278R3

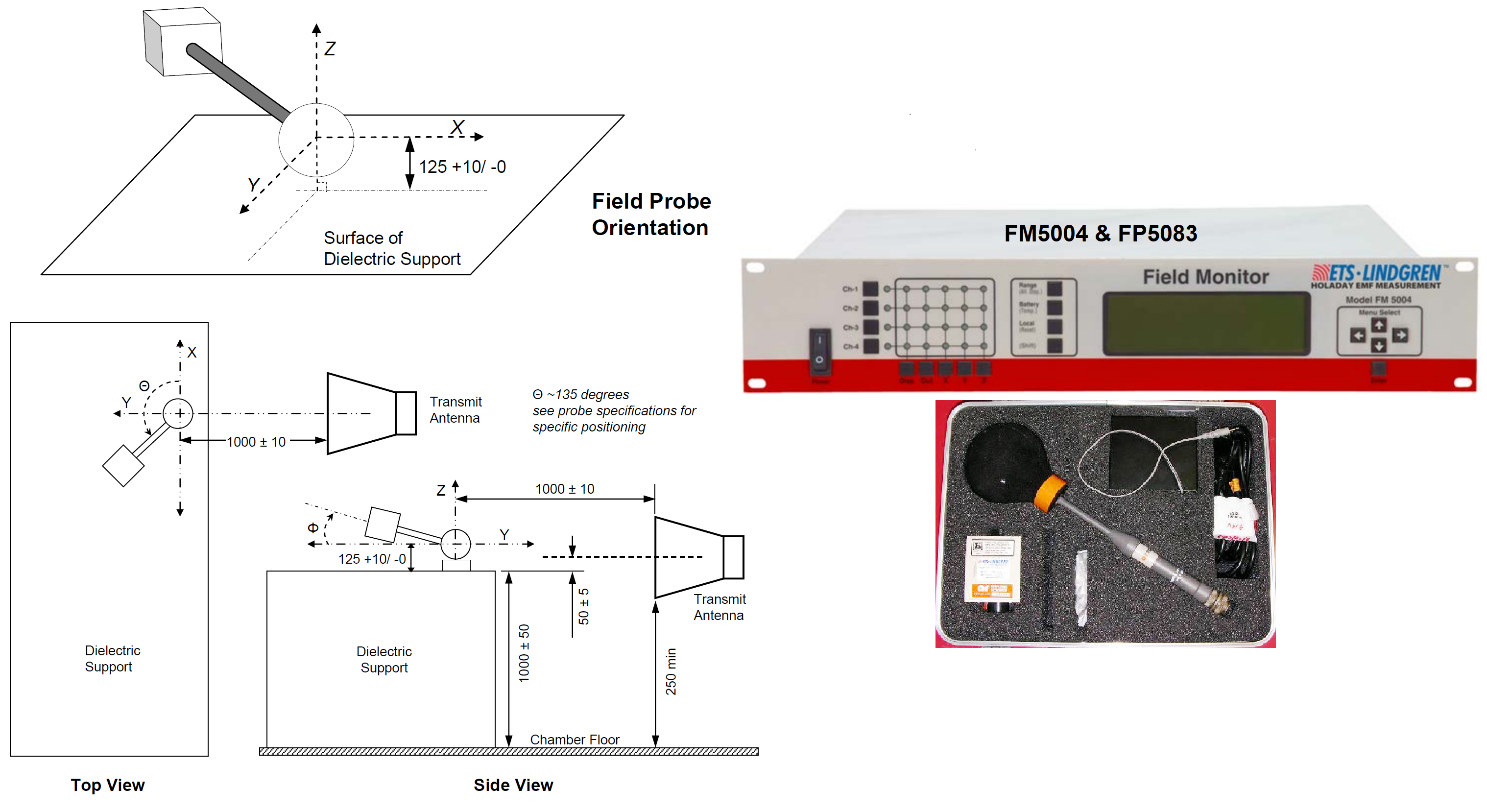

Example of Field Calibration using Field Probe Type B per FMC1278R3

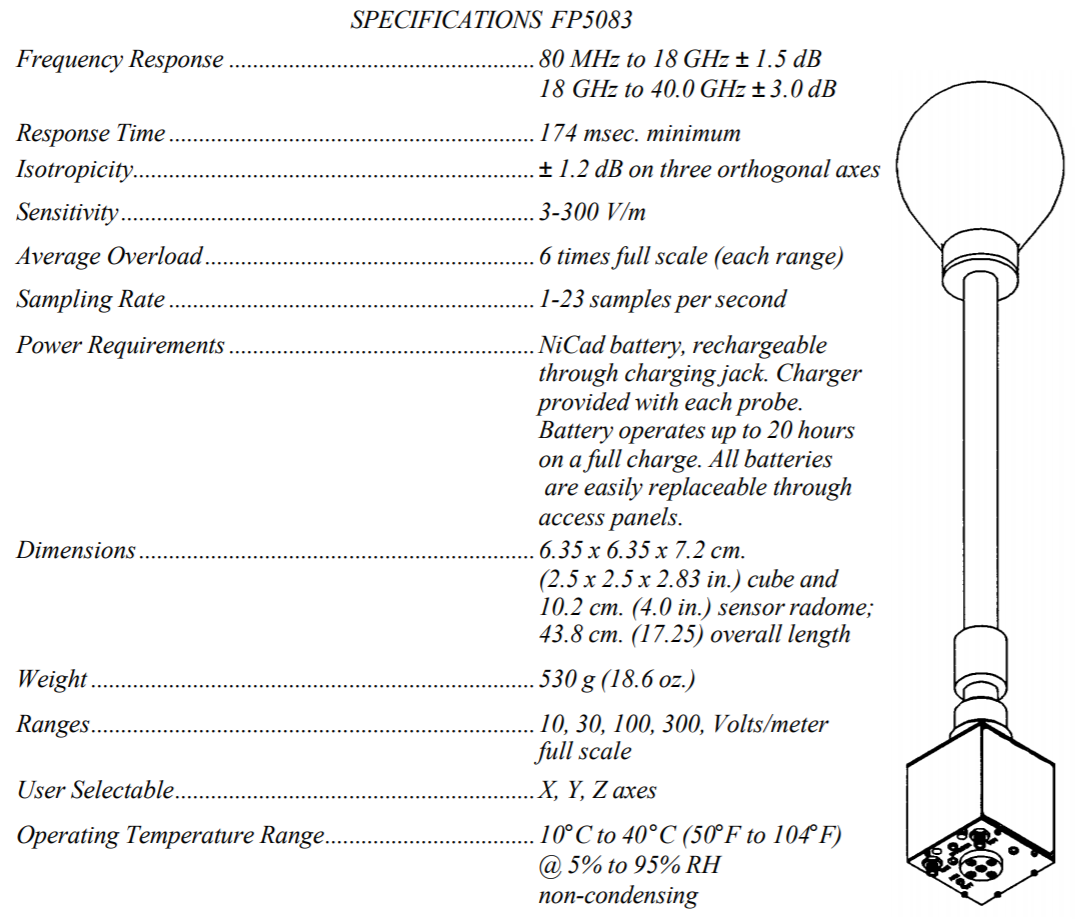

Example of Field Probe Specs (AR FP5082)

References: IEEE 1309:2013, ISO 11452-2, FMC1278 Rev3, 28401NDS02 [8], AR App Note #44

Christian Rosu, Feb 24, 2020

AR_App_Note_44_RF_Field_Probe_Selection.pdf (352.8KB)

Rhode & Schwarz Equipment Calibration Interval:

https://gloris.rohde-schwarz.com/anonymous/en/pages/toplevel/calibration-process.html