Types of load dump transient generators

The high energy content of load dump pulse require specialized pulse generators like classic LCR or DC amplifier based pulse generators.

The LD pulse width and amplitude decrease the smaller the connected load gets. Such requirement can only be fulfilled by using a generator using an energy storage capacitor and a passive pulse-forming network.

Using a programmable DC amplifier to generate LD then pulse amplitude can be set correctly but can't adjust the pulse duration. The DC amplifier based generator outputs considerably more energy being applied to the DUT, which increases the chances to see DUT false deviations.

Curve #1 is unsuppressed LD using generator per ISO 7637-2:2004 Annex E (energy capacitor based LD generator)

Curve #2 is unsuppressed LD using DC amplifier

Curve #3 is suppressed LD using generator per ISO 7637-2:2004 Annex E (energy capacitor based LD generator)

Curve #4 is suppressed LD using DC amplifier

The white area shows the energy absorbed by a varistor or TVS representing the input protection of the DUT.

The grey areas indicate the energy that the DUT is actually exposed to during this test.

The sample above shows 70% higher energy being applied to the DUT by an amplifier based generator compared to the energy generated by an energy capacitor based generator.

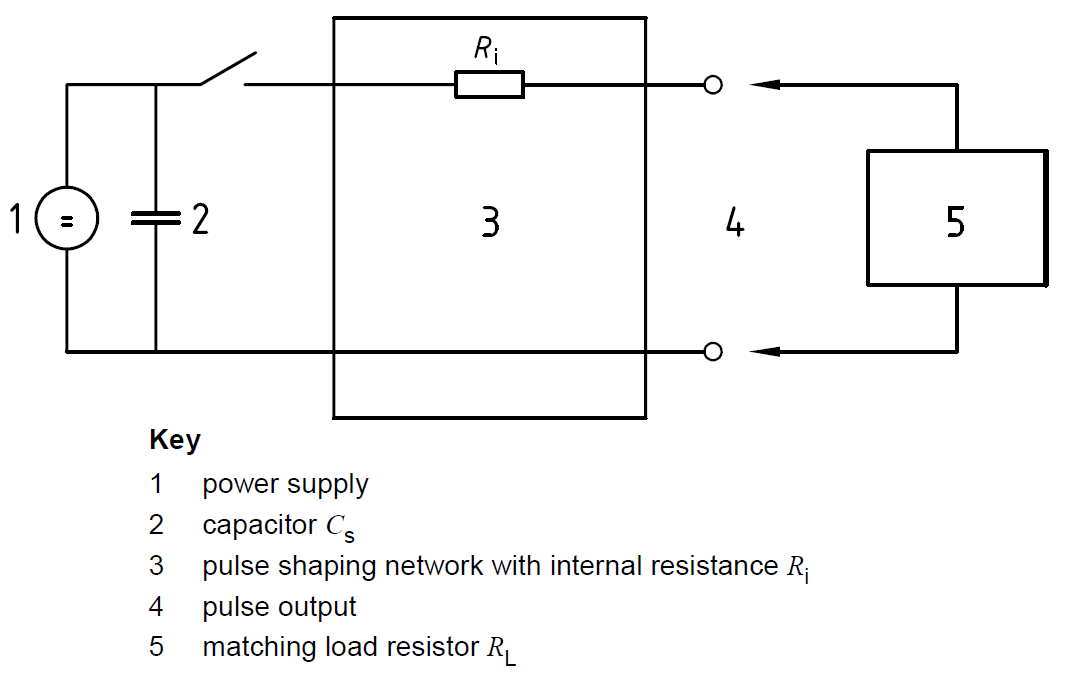

ISO 7637-2:2004 ANNEX-E (Recommended Pulse Generator Type)

E.1 Determination and verification of pulse generator minimum energy capability

E.1.1 Calculation method

This method is used to calculate the energy of the pulse as delivered by the generator to the matching resistor (resistive load RL ), utilizing the measured pulse parameters td and Us.

The transient generator used shall generate double exponential transients, which are a result of capacitive discharges into a pulse shaping network. This type of generator is applicable to pulses 1 (12 V), 1 (24 V), 2a, 3a/3b and 5.

Alternator Load Dump Suppressor

During the LOAD DUMP the difference between two phases reaches up the breakdown voltage of the diodes and then they act as clamping parts. As the difference of potential between each phase is alternative then D1, D2, D3, D4, D5 and D6 act in clamping mode as well as in forward bias.

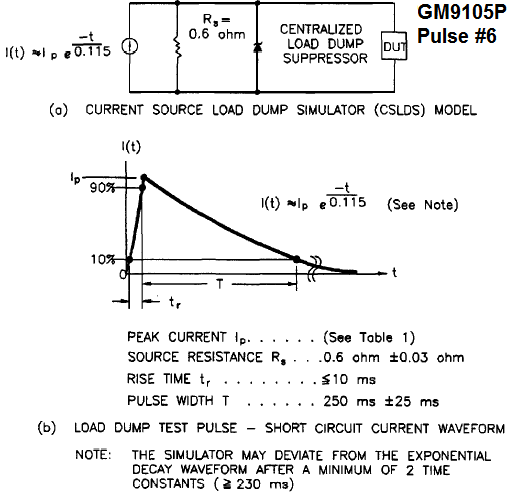

Centralized Load Dump Suppression

The vehicle central transient suppression device is connected directly across the main power supply w/o load resistance. It must absorb the entire load dump energy, and also withstand the full jump-start voltage. It is usually located in the most critical electronic module, however additional suppressors may be placed on other modules to further suppression and to control locally-generated transients.

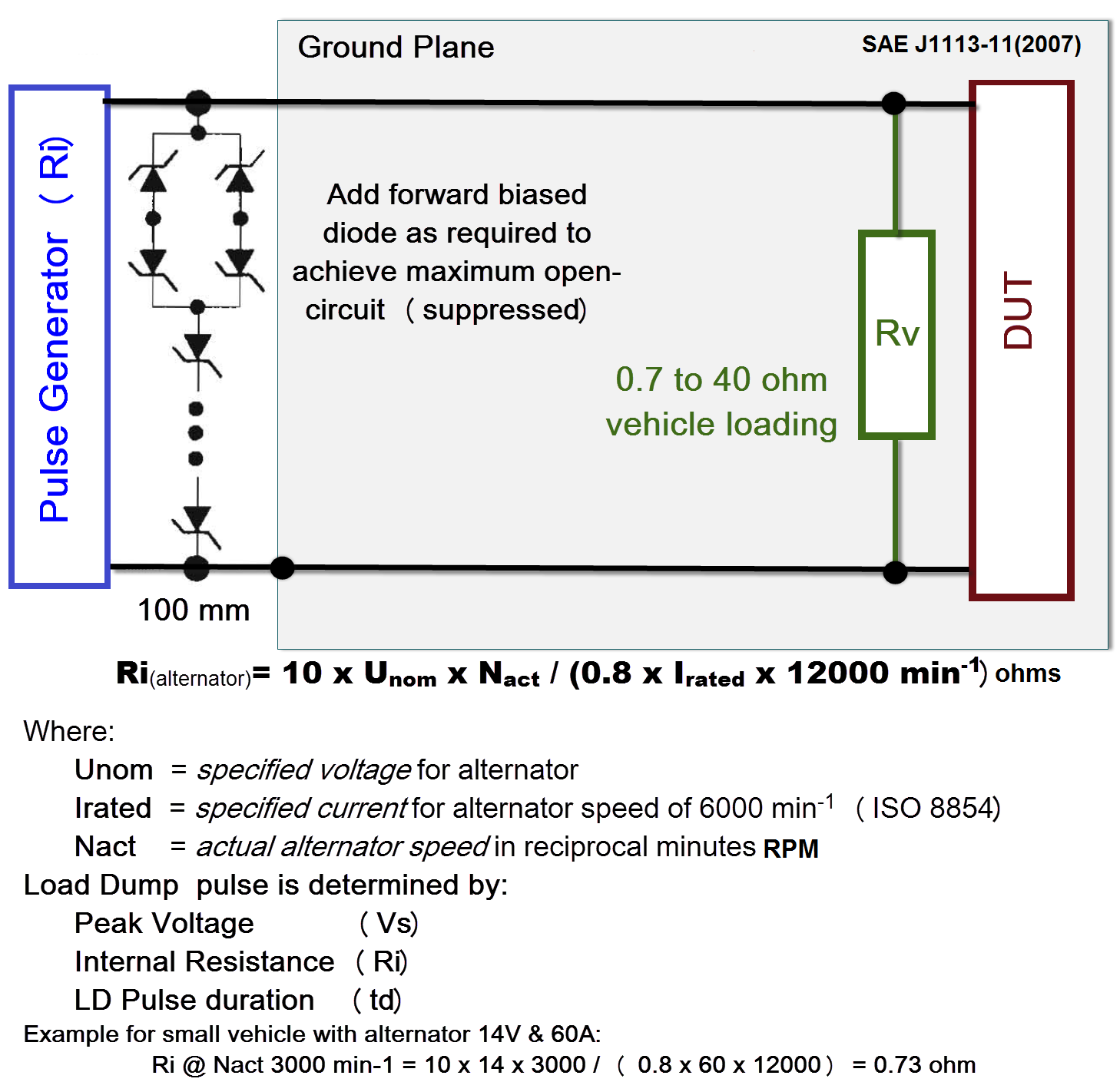

SAE J1113-11 (2007) The Load Dump Pulse Suppressed or Unsuppressed is defined regardless to specification used by (Us) Peak Voltage in Volts, (Ri) Internal Resistance in ohms, and (td) Duration in ms.

The precise characteristics of suppressed load dump pulse varies based on automotive OEM type of centralized LD suppressor used. The testing methodology is periodically adjusted to accommodate new type of electronic devices. As of today most OEM specifications tend to relay on ISO 16750 for Load Dump.

GM9105P Pulse#6 (LD)

GMW3097(2015)

For pulse 5b, use 2 Ω as the source resistance (Ri) per ISO 16750-2. (Us = 34 V +0/-1 V)

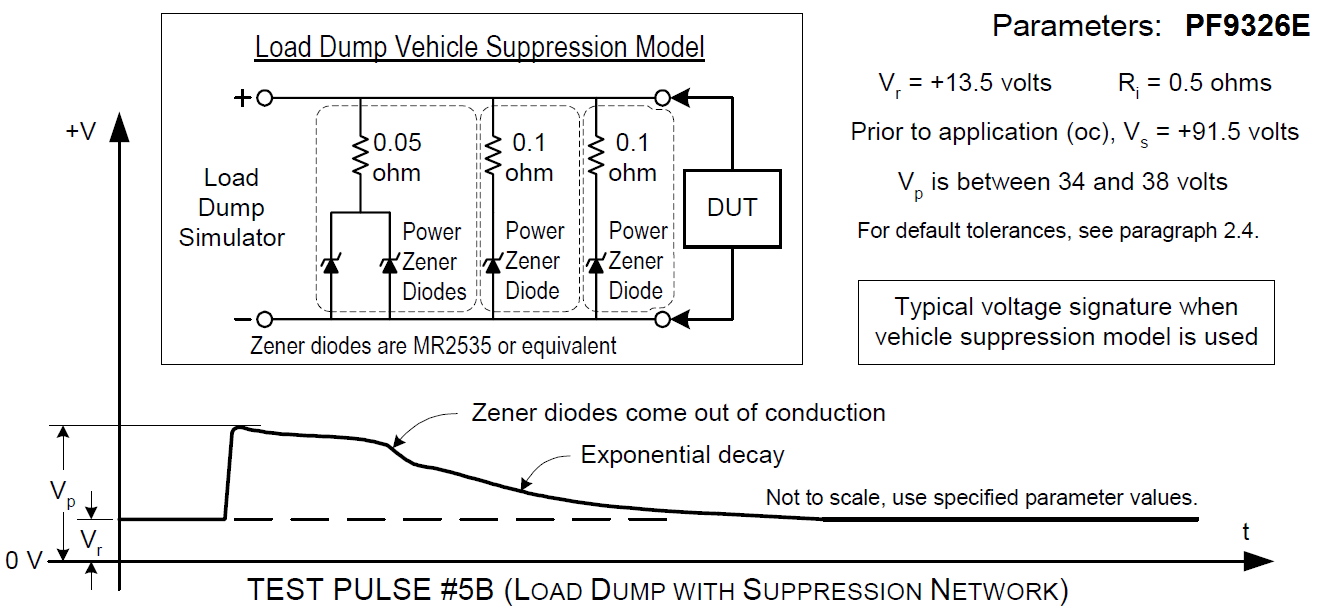

Load Dump Vehicle Suppression Model (PF9326E)

Case #1

- DUT that operate in a vehicle using avalanche/zener diodes in the alternator for LD protection

- suppressed LD must be clamped to the avalanche diode clamp level.

- DUT that provide vehicle LD protection must be tested to verify

- the peak current sinking capability

- the clamping voltage under load

- DUT expected to sink greater than 40 amps peak current (e.g., engine controller)

- tested with an additional 1 ohm of resistance in series with the simulator.

- DUT expected to sink greater than 25 amps peak current (e.g.,airbag control module)

- tested with an additional 2 ohms of resistance in series with the simulator.

- For both cases

- the clamping voltage under load, across the DUT, must be less than 40 volts

- For all other DUT

- open circuit pulse is clamped to an equivalent vehicle system level (40 V maximum, ramping to 35 V max at 100 ms and 25 V max at 200 ms) by connecting a vehicle suppression model in parallel across the load dump output

Case #2

- LD protection in a (single) centralized location

- The engine controller, airbag control module or other modules are not expected to sink load dump current.

- DUT that provide a centralized load dump clamp (e.g. zener protected power distribution center or PDC)

- tested with the full simulator output with no additional series resistance.

- For all other DUT

- this open circuit pulse is to be clamped to an equivalent vehicle with simulated avalanche/zener diode suppression in the alternator system level (36 V maximum) by connecting an alternator simulator suppression model in parallel across the load dump output.

Case #3

- Alternator avalanche/zenner diode load dump protection

- LD test pulse applied to the DUT must be clamped to the avalanche/zener diode clamp level (32 V maximum) by an alternator equivalent suppression model.

Test Pulse #5B as delineated in LP-388C-36

- The suppression network shall be connected to the load dump simulator with a wire length of 20cm and in parallel with the DUT.

- Test all DUT supply terminals together.

- Leads to be load dumped include the following: battery, ignition and any other input and/or output sourced from battery or ignition voltage as configured in a DUT's complete vehicle system.

- Isolate any exerciser circuits, which are meant to simulate other electronic module peripherals to the DUT.

- Do not apply the transient to support equipment.

- The DUT supply voltage shall be provided through the load dump simulator, while the DUT exerciser shall be powered from a separate supply. The negative terminal for the two power supplies shall be connected together.

Suppression Module Verification

- Before the test, the Suppression Module must be verified with 13.5 dc volts offset.

- The output waveform is evaluated using the specifications defined in PF-9326.

- The results of both open and loaded measurements must be documented.

Load Dump Simulator Impedance Verification

The load dump waveform shall be verified with the output open-circuited and shall be evaluated using the specifications defined in PF-9326. Verify that the effect is not caused by the transient interfering with the DUT support equipment. If there is suspicion that the load dump is interfering directly with components of the DUT exerciser, measure the pulse amplitude appearing at the input to the exerciser component which is not meant to be tested. If a substantial amplitude is present, investigate by removing such components.

ES-XW7T-1A278-AB CI 240

A load dump typically occurs during a vehicle-to-vehicle jump start when the jumping vehicle can experience a significant load dump or due to a loose battery terminal. It represents sudden disconnection of load from alternator. Max voltage ESC is exposed to is about 45 V.

- Open Circuit: Vbat+ 60V, 300 ms

- Loaded Circuit: (R = 0.7W): Vbat+30 V, 150 ms

References:

Load Dump Phenomenon by Roland Spriessler & Markus Fuhrer

Various Electronic Components Automotive OEM EMC Specs

Updated on Apr 17, 2017 by Christian Rosu